How all sustainable aviation fuel (SAF) feedstocks and production technologies can play a role in decarbonising aviation

Sustainable aviation fuel (SAF), hydrogen and electric all have a role to play in the decarbonisation of aviation. SAF is vitally important as it can address decarbonisation of fuel over its lifecycle, and this is now available to be used in all turbine engines including in mid and long-range aircraft. Therefore, understanding the feedstock landscape as well as the technology pathways is integral to maximising the production and supply of SAF.

The production of SAF starts with one of five main families of raw materials: oils and fats, sugar and cereal, municipal solid waste, wood and agricultural residue, or renewable energy and carbon (see image 1) used to replace a proportion of the crude oil feedstock.

Each of these feedstocks uses a particular production technology, with each specific technology pathway needing approval from the fuel standard body ASTM before being commercially deployed.

There are two ways of producing SAF, with standalone units or through co-processing. Standalone units use sustainable feedstocks to produce the synthetic kerosene (SK), that is then blended with conventional jet fuel to produce SAF. Whilst producing SAF through co-processing up to 5% sustainable feedstocks being are processed alongside fossil feedstocks through hydro-processing in the refinery.

With standalone units the feedstock is converted in a biorefinery into SK and then certified to the relevant annex in ASTM D7566 standard. The approved technology pathways and associated feedstocks are shown in table 2. This SK is then blended up to 50% with conventional jet fuel and certified to ASTM D1655 or Defence Standard 91-091 and is supplied as a conventional Jet A/ Jet A-1 fuel.

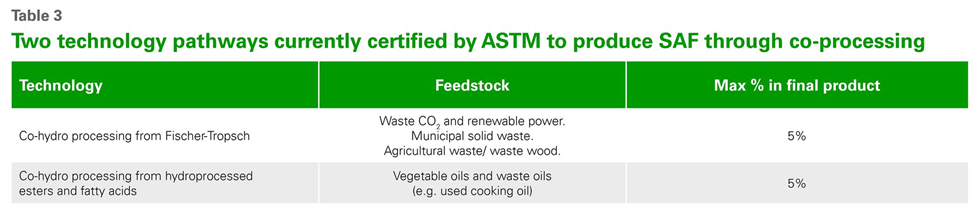

Two of the technology pathways and associated feedstocks are approved to produce SAF through co-processing. These feedstocks are shown in table 3.

Hydrotreated esters and fatty acids (HEFA)

Driven by the lower cost of capital and the availability of feedstocks which are close in energy density to fossil fuels, most of the SAF supplied today is derived using the hydrotreated esters and fatty acids (HEFA) pathway. The primary feedstocks for this conversion pathway include waste fats, oils, and greases and following pre-treatment these can be processed in standard hydrocracker units.

While HEFA synthetic paraffinic kerosene (SPK) is currently the only commercial pathway being used at scale to produce SAF, current feedstocks are limited. There is need for rapid commercial large-scale sustainable feedstock mobilisation. Alternative high energy crops that are being trialled or have already been approved as HEFA feedstocks, include algae, camelina, pennycress, tallow tree and carinata. We promote the use of cover crops (crops grown for the protection and enrichment of the soil), such as carinata, as a feedstock when they do not require additional land demand and contribute to sustainable farming practices – supporting soil carbon accumulation, soil quality and biodiversity. bp has already entered into a long-term strategic offtake and market development agreement with Nuseed to purchase carinata oil.

While an increasing number of flights have been fuelled by SAF produced from the HEFA pathway, limited feedstocks mean we expect to see SAF produced from alcohol to jet (AtJ), Municipal Solid Waste (MSW) and second generation (2G) biomass increasing significantly beyond 2030.

First generation alcohol to jet (AtJ)

Alcohol to jet (AtJ) is another technology that has an approved pathway. It is a method whereby sugary, starchy biomass such as sugarcane and corn grain are converted via fermentation into ethanol or other alcohols which can then be shipped or piped before being converted to fuel. These feedstocks are easy to grow and transport by train, however sugarcane must be processed into ethanol within 48 hours of being cut. To achieve low logistical costs, reduce carbon emissions from transport and make better use of infrastructure, ethanol plants benefit from being placed close to feedstock production mills as well as to refineries.

In some regions, particularly in the Americas, feedstock such as corn and sugarcane are currently commercially used for fuel production. Demand from sectors such as ground fuel and petrochemicals means however that there is limited feedstock available to aviation. As a result, there are no commercial SK plants using the AtJ production pathway.

Timing is therefore the important factor to consider with the AtJ pathway. As ground fuels move more towards electrification this will free up feedstock supply for the aviation sector which in turn will lead to commercial SAF production from this pathway.

Another consideration with the AtJ pathway is that the reduction in carbon intensity is not as strong when compared to the alternative technologies. Implementation of solutions such as carbon capture and storage technology will be key to lowering greenhouse gas emissions (GHG) using this technology. Other options to evaluate include the use of biogas in place of natural gas in mills and converting farm machinery to run on biofuels rather than fossil fuels.

Fischer-Tropsch (FT) for municipal solid waste (MSW)

As with AtJ there are approved pathways for this production. There is also feedstock availability, therefore producers are focusing on technology developments that can reduce the relatively high capital costs.

For SAF produced from MSW using Fischer-Tropsch (FT) technology the main environmental gain is derived from the fact that the waste would otherwise be left to decompose in landfill sites. According to the World Bank, the world generates more than 2 billion tonnes of MSW annually; a figure that’s expected to grow to 3.4 billion tonnes by 2050. However, while access to MSW as a feedstock is widely available across the globe and it is typically a lower cost feedstock than other raw materials, in some regions aviation is in competition with other sectors, including the energy industry, for access to MSW.

In the EU, bp is – among other feedstock and technology pathways – advocating for recycled carbon fuels made from the non-organic portion of MSW to be recognised as SAF under the EU’s planned SAF blending mandate. We are not however advocating for the use of recycled plastics as a standalone feedstock source for SAF.

It’s a capital-intensive process to get the infrastructure in place, as production includes producing an FT wax which is then refined into SK before being blended into SAF. The good news here is that there is ongoing work to research and develop technologies that will lead to more efficient production. For example, bp and Johnson Matthey co-developed and co-own a simple-to-operate and cost-efficient FT technology that can operate both at large and small scale to economically convert synthesis gas, generated from sources including MSW, into long-chain hydrocarbons suitable for the production of SAF.

Technologies to convert 2nd generation biomass

For these feedstocks there is no pathway that is commercially deployed. However, work is progressing with ASTM for pyrolysis of biomass through both standalone production and co-processing in refineries. Once a pathway is approved, demo plants would then need to be established to prove the technology at scale before it is commercially deployed.

While second generation biomass such as agricultural and forestry residue is in vast supply as a feedstock, once aggregated it must be transported by road or rail – as a solid it can’t be moved via pipeline. Ultimately this means we’ll end up with small production plants near where forestry residues are processed. While a handful of these plants already exist, none are being used currently to produce SAF.

Fischer-Tropsch (FT) for power-to-liquid

Possibly one of the most promising pathways for SAF in the longer term is power-to-liquid (PtL) technology (producing what is called eSAF), which is still very much in its infancy. Renewable electricity (from sources such as solar, hydro or wind) is used in an electrolysis process to extract hydrogen from water. This green hydrogen is first used to convert carbon dioxide (from the air, biogenic or industrial sources) to carbon monoxide. Then using FT synthesis technology, this carbon monoxide along with more green hydrogen is converted into a wax that can be upgraded to SK.

The challenge currently with eSAF technology is cost. To be commercially viable and competitive with conventional jet fuel this fuel (which is expected, in the short-term, to be three to eight times the cost of conventional jet fuel and up to around four times the cost of SAF made from HEFA) needs to be produced at low cost. The availability and cost of the renewable energy and carbon dioxide, as well as the expansion and improvement of green hydrogen plants must be addressed to meet market demand.

Carbon dioxide could be secured from existing industrial sources such as plaster, concrete and food manufacturing companies as well as direct air carbon capture (a technology which removes carbon dioxide from the atmosphere). While sectors such as the steel and cement industries continue to explore technical solutions to reduce the carbon they emit, eSAF producers can benefit from using this cost-effective carbon dioxide source.

In terms of increasing green hydrogen production, as it is required by many industries to decarbonise, aviation will benefit from the focus being placed on increasing production. In addition, German mandates have specific requirements for eSAF from 2026 and European mandates currently being finalised are expected to follow suit in 2030.

Longer-term, eSAF will also benefit from on-going work in developing new pathways in addition to those already approved. In particular, methanol to jet could provide a competitive alternative production method for these feedstocks.

In summary, aviation is one of the hardest-to-abate sectors when it comes to reducing fuel lifecycle carbon emissions, with SAF currently the only way to decarbonise the industry at pace and at scale. Utilising a wide range of feedstocks is key to the production of SAF, as is the ongoing evolution of production pathway options. bp will continue to work with stakeholders across the energy supply chain as well as governments, NGOs, authorities and other businesses to help meet future SAF demand.

Airlines

How all sustainable aviation fuel (SAF) feedstocks and production technologies can play a role in decarbonising aviation – Air bp

27th Apr 2023, 15:38. Written by